“Don’t focus on the outcome, focus on the process.”- unknown

- STEP 1: To begin the screen printing process, our design artist creates your design using Adobe Illustrator. Once it has been approved, we print it using jet black ink from an Epson printer onto a 13×19 sheet of transparent film.

- STEP 2: While the transparency is printing, its time to prep the screens. We first use a degreaser to make sure there inst any dirt particles or residue left on the screen. Then, in a light safe room, we apply the emulsion. After a smooth even coat, we leave it in the dark room to dry.

- STEP 3: When the screen is completely dry, its time to expose it. Still in a light safe room , we center the transparency onto the screen and place it in our exposure unit. Just about 7 seconds later, our screen should be properly exposed and it’s on to the next step.

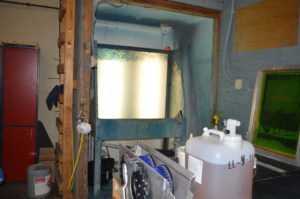

- STEP 4: Now we need to take the exposed screen to our wash out station. Be careful not to expose the screen to too much light because the screen is still very sensitive. A quick spray with a pressure washer is perfect, making sure to spray out all the unhardened emulsion.

- STEP 5: Now that the screen is dry, we are almost ready to print. Check the screen for any pin holes or any areas around the screen that didn’t get coated by emulsion. We are going to have to tape these areas up so when we print the ink wont go through.

- STEP 6: Now we are ready to load the screen to our press. Whether its an automatic or manual press, the process is the same. We determine the off contact and screw the screen to the press.

- STEP 7: Add the ink onto the screen and with the proper squeegee we are now ready to print. Lower the screen and push the squeegee across the screen to print the ink onto the shirt. Now raise the screen and check it out.

- STEP 8: Finally, we remove the shirt carefully from the pallet and run it through our conveyor dryer. We have to make sure the ink reaches 350 degrees so the ink will cure and become permanent. Once its dry the process is complete and the packaging begins.

What is screen printing good for?

Screen printing works best on performance shirts (100% polyester), 100% cotton, 50/50 cotton poly blend, and various tri blend shirts as well. Screen printing is a process, so no matter what the quantity of shirts are, the process is still the same. Furthermore, adding more than 1 color means we have to make a screen for every additional color. This makes the process longer, resulting in a more expensive shirt. This being said, screen printing is ideal when printing the same design on multiple shirts with just a few colors of ink. However, the more you order, the cheaper they become.